Class 0 Oil-free Converter

To make discharged lubricated oil from compressor to total oil free in class 0

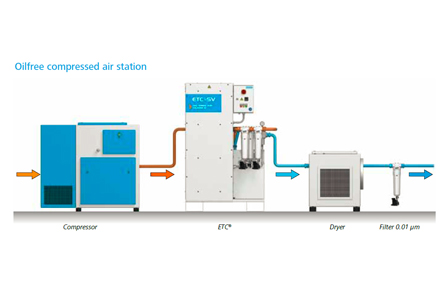

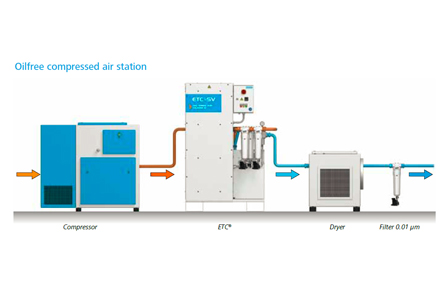

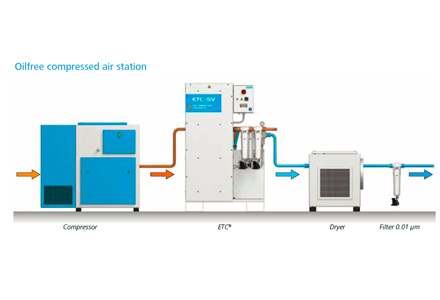

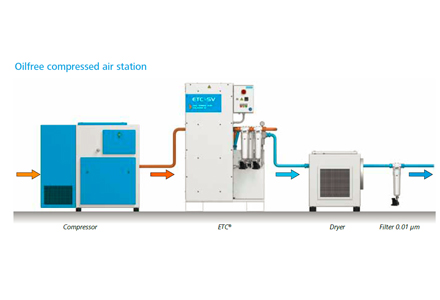

The way to oil-free compressed air

The ETC® operating principle

Through the process of catalytic oxidation, Rotorcomp ETC converters actively transform the oil and hydrocarbons in compressed air into water and CO2. ETC Converter continuously supplies Class 0 compressed air, in accordance with ISO 8573-1, with a residual oil content of

With its catalytic technology for the treatment of compressed air, ETC provides a technical solution that has been successfully used for many years in the automotive and chemical industries.

For compressed air upstream of a converter that has an oil content of max. 200 mg/Nm3, ROTORCOMP guarantees oil-free Class 0 compressed air downstream of the converter.

In contrast to conventional filter systems (e.g., activated carbon), the air quality is constantly maintained. Saturation and the risk of a breakthrough by hydrocarbon compounds are reliably prevented.

In contrast to oil-free compressors, the compressed air quality does not depend upon the hydrocarbon content of the ambient air.

The operation of the catalytic converter is independent of the temperature and humidity of the compressed air to be treated.

ETC-SV – Catalytic air treatment

Features and product advantages

1. Guaranteed oil-free compressed air in accordance with ISO8573-1 Class 0 (residual oil content ≤ 0.0025 mg/Nm3), confirmed by independent TUV measurements.

2. Absolutely secure system since a protective shutdown unit prevents oil-containing compressed air from entering into the network in the event of a malfunction.

3. Guarantee on the operation of the catalyst for 5 years for hydrocarbon concentrations at the ETCR inlet of up 200 mg/Nm3.

4. Lower energy consumption to a max. of 0.01 kWh/m3 through Improved insulation of converter and housing.

5. Minimizes significant the bacteria, fungus and microbial diversity content in the compressed air.

6. Pure and neutral condensate (Öl

7. Irreversible separation of silicon monomeres out of the compressed air.

8. Partial load capacity of 20 to 110 % of the nominal flow rate when using the optional VS module.

9. Increased service life for downstream dryer.

ETC-SV Technical Data:

| Model | Air flow @7bar | Max. Pressure | Pipe Diameter | Weight | Dimension(L*W*H) | Specific

energy consumption during operation |

Energy

consumption @ normal flow |

Installed

power |

| N³/min | Bar | MM | kg | mm | Kwh/N³ | kwh | kw | |

| ETC-SV04 | 0.4 | 16 | 15*1.5 | 80 | 700*340*1400 | 0.009 | 0.2 | 1 |

| ETC-SV1 | 1 | 16 | 18*1.5 | 140 | 860*455*1455 | 0.009 | 0.5 | 1.2 |

| ETC-SV2 | 2 | 16 | 28*2 | 160 | 860*455*1655 | 0.009 | 1.1 | 2.5 |

| ETC-SV5 | 5 | 16 | 35*2 | 360 | 1175*620*1890 | 0.007 | 2.1 | 5 |

| ETC-SV7 | 7 | 16 | 42*2 | 410 | 1175*620*1890 | 0.006 | 2.5 | 5 |

| ETC-SV10 | 10 | 16 | 42*2 | 590 | 1630*615*2100 | 0.005 | 3.0 | 10 |

| ETC-SV15 | 15 | 16 | DN50 | 770 | 1630*880*2100 | 0.005 | 4.5 | 10 |

| ETC-SV20 | 20 | 16 | DN65 | 900 | 1900*1140*2150 | 0.005 | 6.0 | 15 |

| ETC-SV30 | 30 | 16 | DN65 | 1100 | 1900*1140*2150 | 0.005 | 9.0 | 21 |

| ETC-S40 | 40 | 16 | DN80 | 1500 | 2200*900*2240 | 0.005 | 12.0 | 28 |

| ETC-S50 | 50 | 16 | DN100 | 1700 | 2250*900*2240 | 0.005 | 15.0 | 28 |