NK High-end Series Screw Compressor

EVO High-end Series Screw Compressor

LGCD Direct Driven Screw Compressor

Advantages of NK High-end Series Screw Compressor:

Hot sale! Oil Lube Rotary Air screw Compressor

1. World-leading ROTORCOMP integrated air end made in Germany

2. 5 years warranty

3. Unique Extraordinary cooling system design

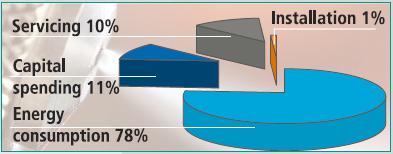

4. Economic running costs

5. ISO, TUV, GA, SGS certificates

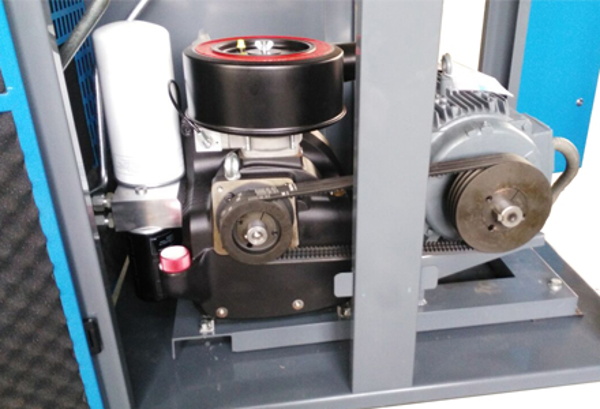

All our NK high-end air screw compressors assembled with unique series of EVO®-NK compact units that are oil-injected

screw compressor modules integrated the main parts

of a compressor system.

This solution is the best possible

way to build a reliable, compact and cost-efficient complete

compressor package with ultimate efficiency, low noise

and the highest quality standards.

Why use NK high-end rotary screw air compressor?

Economic running costs

Capacity,0-100% adjustment When the gas consumption is reduced, the capacity decreases, following motor current is also reduced, our NK high-end air screw compressor is running without capacity, if this status keeps for a long time, compressor automatically shut down. While air consumption increases, compressors recovers. The energy-saving effect is optimal.

Good environmental adaptability

Extraordinary cooling system design, especially for the high-temperature, high humidity environment. Excellent vibration isolation and noise reduction measures, so that the installation of our NK high-end air screw compressor no need for a dedicated basis, only to leave a minimum ventilation and maintenance space, you can settle your compressor.

Frequency converters (optional)

The frequency converter minimises idle times and optimises supply

with fluctuating compressed air requirements. Start-up peaks are

avoided and the compressor’s delivery rate is controlled continuously

– that saves electricity costs! The total costs for your compressed air

supply are significantly reduced and investment costs are amortised

in the shortest possible time.

Standard compressor

Savings after 5 years when using our Nk high-end compressor:

Parameters

| Mode | Capacity m3/min | Power/

(KW) |

Weight/

Kg |

Noise/

dB(A) |

Dimension/

L×W×H(mm) |

||||

| 7 bar | 8 bar | 10 bar | 13 bar | 15 bar | |||||

| LGFD7.5 * | 1.30 | 1.20 | 1.00 | 0.75 | 0.60 | 7.5 | 290 | 65±3 | 900×650×1290 |

| LGFD11 * | 1.70 | 1.60 | 1.50 | 1.15 | 0.90 | 11 | 350 | 65±3 | 900×650×1290 |

| LGFD15 * | 2.25 | 2.05 | 1.85 | 1.50 | 1.20 | 15 | 360 | 67±3 | 900×650×1290 |

| LGFD18.5* | 3.10 | 2.90 | 2.55 | 2.10 | 1.80 | 18.5 | 565 | 70±3 | 790×1360×1220 |

| LGFD22* | 3.60 | 3.40 | 3.00 | 2.50 | 2.30 | 22 | 600 | 70±3 | 790×1360×1220 |

| LGFD30* | 5.20 | 4.90 | 4.40 | 3.70 | 3.00 | 30 | 810 | 72±3 | 930×1660×1530 |

| LGFD37* | 6.30 | 6.00 | 5.40 | 4.70 | 4.10 | 37 | 830 | 72±3 | 930×1660×1530 |

| Note: | |||||||

| 1. The above parameters and color are designed according to customer needs, the parameters are for reference only, the final parameters of the drawings shall prevail; | |||||||

| 2. According to user requirements and needs, to join way: air/water cooling, oil content, weight, appearance size according to the need to design, to the final order and the technical agreement shall prevail; | |||||||

| 3. The company to change the above parameters subject to change, without prior notice. | |||||||